then select a valid CSV file.

then select a valid CSV file.The general and calendar settings define essential site properties such as its name, time zone, unit system, and default data source. They also configure the calendar, which structures scheduling periods. The calendar’s period definitions—like shifts or days—determine the level of detail in planning.

|

General |

|

|

Site Name |

Defines the name of the site. |

|

Site Time Zone |

Sets the time zone of the site.

|

|

Default data source |

Optionally defines the default data source for publishing data to the EPF Model Repository. This data source will be the default for all file publishing. If no location is selected, you are prompted to select a location whenever you publish a file. |

|

Reduce production to achieve blend |

Defines whether the schedule can dynamically slow down this site’s resources to achieve a desired blend for a destination with a quality objective configured. For more information, refer to Reduce production to achieve blend below. |

|

Rehandle Group Capacity |

Each rehandle group can have an Unlimited or Limited capacity. When limited, the schedule ensures that the total flow through the associated movements/arcs doesn’t exceed the combined capacity of the resources that service this group. For more information, refer to Rehandle groups below. |

|

Unit System |

Specifies whether the site uses the metric or US customary unit system. This setting is essential to ensure consistency with your mine’s standards and is particularly important for calculations such as haulage travel times, where unit accuracy directly impacts scheduling and performance metrics. |

The site options can lock a site to prevent changes, clone a site to create a duplicate, and rebuild the schedule to refresh planning data.

The Lock Site option prevents further changes to a site’s configuration or schedule. This is useful for preserving a specific site state during critical planning or review phases.

Click Lock Site again to unlock the site.

To lock a site, click Lock Site. This action immediately applies the lock and updates the site’s status across all open instances.

Once a site is locked:

The name of the user who performed the lock and the date of the action are recorded.

Any open instances of the site are automatically reloaded to reflect the locked state.

The lock status is clearly displayed in two places:

The site title bar

General Site Properties

Any user can lock or unlock a site

When a site is locked, the software takes a snapshot of the current global configuration settings. These settings remain in effect while the site is locked. Once the site is unlocked, the most recent global configuration settings are reapplied.

Although configuration and scheduling changes are restricted, several actions remain available:

Reports can still be modified and exported, but cannot be saved until the site is unlocked.

Export functions remain fully enabled, including:

Export Scene to Image

Export Stage Plan

Publish Data Feed Out

Cloning a site creates a fully self-contained copy of the original site, including all associated data and configuration settings. This is useful for testing changes, running alternative scenarios, or preserving a snapshot of a site at a specific point in time.

To clone a site, click Clone Site. The system will begin creating a duplicate of the selected site.

During the cloning process, the original site remains fully operational. For example, if you're cloning a site named KSGM, the new site (e.g., KSGM (2)) will be created in the background while KSGM continues to function normally.

While a site is being cloned, the new site is temporarily unavailable. Once the cloning process is complete, the cloned site will appear in a Ready state, meaning it’s stopped by default and not yet active.

If you don’t see the cloned site in your list, check that the Active Site filter is not applied. Since cloned sites are initially inactive, they may be hidden by this filter.

You can rebuild the schedule for a full schedule recalculation for the current site.

Clicking Rebuild Schedule opens a dialog where you can optionally enter a reason for the rebuild. This note can help provide context for other users or for audit purposes.

When you confirm by clicking Rebuild, a command is sent to the XECUTE server to clear the scheduling cache and re-run the schedule from scratch. This process ensures that all calculations are refreshed based on the latest inputs.

Rebuilding the schedule affects all users connected to the site. Once the rebuild is complete, the updated schedule data is automatically pushed to all users.

The site calendar defines the scheduling and reporting periods used throughout the site. It determines how time is segmented for planning, reporting, and execution.

The calendar provides the temporal structure for all scheduling and reporting activities in XECUTE. It defines the start and end of each period, which can represent shifts, days, weeks, or any custom duration depending on the level of detail required for your operation.

Smaller periods—such as hours or 12-hour shifts—offer more granular control and visibility. For example, using 12-hour shift periods allows you to track metrics like:

Tonnes mined by a specific resource

Distance travelled by equipment within the shift

Total material extracted from a pit during that period

This level of detail directly influences how precisely you can schedule and report on operational performance.

Period-based data such as time usage availability, utilisation, efficiency, production rates, and objective targets are all entered per period. This means the value you set for a given field applies uniformly across the entire period, making the calendar structure critical for accurate planning and reporting.

When a new site is created, the software automatically generates a default calendar consisting of 70 periods, each split into two 12-hour shifts per day (DayShift and NightShift). This provides a ready-to-use structure for short-term scheduling.

You can configure a calendar to suit your operational needs. Periods can be of any duration, and the length of each period can vary over time. For example, you might start with daily shifts, then transition to weekly or monthly periods as the schedule progresses.

The table below shows a custom calendar with 10 periods. The first 8 periods alternate between DayShift and NightShift, each lasting 12 hours. The final two periods are labelled Day and span 24 hours each.

|

Period Number |

Period Name |

Period Start |

Period End |

|---|---|---|---|

|

1 |

DayShift |

07/08/2026 06:00 AM |

07/08/2026 06:00 PM |

|

2 |

NightShift |

07/08/2026 06:00 PM |

08/08/2026 06:00 AM |

|

3 |

DayShift |

08/08/2026 06:00 AM |

08/08/2026 06:00 PM |

|

4 |

NightShift |

08/08/2026 06:00 PM |

09/08/2026 06:00 AM |

|

5 |

DayShift |

09/08/2026 06:00 AM |

09/08/2026 06:00 PM |

|

6 |

NightShift |

09/08/2026 06:00 PM |

10/08/2026 06:00 AM |

|

7 |

DayShift |

10/08/2026 06:00 AM |

10/08/2026 06:00 PM |

|

8 |

NightShift |

10/08/2026 06:00 PM |

11/08/2026 06:00 AM |

|

9 |

Day |

11/08/2026 06:00 AM |

12/08/2026 06:00 AM |

|

10 |

Day |

12/08/2026 06:00 AM |

13/08/2026 06:00 AM |

To create a custom calendar, make a CSV file with two columns. The columns must be in this order and have these column names:

Period Name: A label for the period (e.g., DayShift or Week1)

Start Date: The start date and time of the period

A CSV file for the calendar in the example above is shown below.

|

Period Name |

Period Start |

|---|---|

|

DayShift |

07/08/2026 06:00 AM |

|

NightShift |

07/08/2026 06:00 PM |

|

DayShift |

08/08/2026 06:00 AM |

|

NightShift |

08/08/2026 06:00 PM |

|

DayShift |

09/08/2026 06:00 AM |

|

NightShift |

09/08/2026 06:00 PM |

|

DayShift |

10/08/2026 06:00 AM |

|

NightShift |

10/08/2026 06:00 PM |

|

Day |

11/08/2026 06:00 AM |

|

Day |

12/08/2026 06:00 AM |

|

End |

13/08/2026 06:00 AM |

A final "dummy" row is required to define the end of the last period – it won’t be an actual period in the scheduling calendar.

To import a calendar, click Import  then select a valid CSV file.

then select a valid CSV file.

The calendar preview displays all periods and their associated attributes from the currently imported calendar.

Each represents a single period.

Each column shows a property of that period, such as:

Period Number

Period Name

Period Start

Period End

Any custom grouping fields you’ve defined

Two other columns, Duration in Hours and Duration In Days, are automatically generated. These are calculated as the time difference between the start of the current period and the start of the next.

|

Period Number |

Period Name |

Period Start |

Period End |

Duration in Hours |

Duration in Days |

|---|---|---|---|---|---|

|

1 |

DayShift |

07/08/2026 06:00 AM |

07/08/2026 06:00 PM |

12 |

0.5 |

|

2 |

NightShift |

07/08/2026 06:00 PM |

08/08/2026 06:00 AM |

12 |

0.5 |

|

3 |

DayShift |

08/08/2026 06:00 AM |

08/08/2026 06:00 PM |

12 |

0.5 |

|

4 |

NightShift |

08/08/2026 06:00 PM |

09/08/2026 06:00 AM |

12 |

0.5 |

Calendar groupings allow you to define custom fields that group multiple scheduling periods into named categories, such as Week, Month, or Operational Phase. Groupings can be used to apply logic across a range of periods.

|

Week |

Period Number |

Period Name |

Period Start |

Period End |

|---|---|---|---|---|

|

Week1 |

1 |

Sunday |

02/08/2026 12:00 AM |

03/08/2026 12:00 AM |

|

Week1 |

2 |

Monday |

03/08/2026 12:00 AM |

04/08/2026 12:00 AM |

|

Week1 |

3 |

Tuesday |

04/08/2026 12:00 AM |

05/08/2026 12:00 AM |

|

Week1 |

4 |

Wednesday |

05/08/2026 12:00 AM |

06/08/2026 12:00 AM |

|

Week1 |

5 |

Thursday |

06/08/2026 12:00 AM |

07/08/2026 12:00 AM |

|

Week1 |

6 |

Friday |

07/08/2026 12:00 AM |

08/08/2026 12:00 AM |

|

Week1 |

7 |

Saturday |

08/08/2026 12:00 AM |

09/08/2026 12:00 AM |

|

Week2 |

8 |

Sunday |

09/08/2026 12:00 AM |

10/08/2026 12:00 AM |

|

Week2 |

9 |

Monday |

10/08/2026 12:00 AM |

11/08/2026 12:00 AM |

|

Week2 |

10 |

Tuesday |

11/08/2026 12:00 AM |

12/08/2026 12:00 AM |

A calendar that groups periods by the week they belong to

A grouping field is a custom calendar column that assigns multiple periods to a shared label or category. For example, using a Week grouping, periods 1-7 could be grouped under Week1, and periods 8-14 could be grouped under Week2.

You define grouping fields in the calendar editor. In the Group Name property, enter a name for the grouping field, then click Add. This creates a new column in the calendar, to the left of the other fields.

The initial value for each period in a new grouping column defaults to the column name. To customise the grouping value for each period, you define the grouping field values in the CSV and then reimport the file.

In the calendar CSV file, add the grouping column to the left of the default columns (Period Name, Period Start). For each period, enter the appropriate grouping value (e.g., Week1, PhaseA…).

An example CSV for the calendar above is shown below.

|

Week |

Period Name |

Period Start |

|---|---|---|

|

Week1 |

Sunday |

02/08/2026 12:00 AM |

|

Week1 |

Monday |

03/08/2026 12:00 AM |

|

Week1 |

Tuesday |

04/08/2026 12:00 AM |

|

Week1 |

Wednesday |

05/08/2026 12:00 AM |

|

Week1 |

Thursday |

06/08/2026 12:00 AM |

|

Week1 |

Friday |

07/08/2026 12:00 AM |

|

Week1 |

Saturday |

08/08/2026 12:00 AM |

|

Week2 |

Sunday |

09/08/2026 12:00 AM |

|

Week2 |

Monday |

10/08/2026 12:00 AM |

|

Week2 |

Tuesday |

11/08/2026 12:00 AM |

|

Week2 |

End |

12/08/2026 12:00 AM |

Reimport the CSV into the software. The software matches the grouping field defined in the calendar with the column in the CSV and accordingly applies the values to the periods.

If you encounter the error:

Field index must be included in [0, FieldCount[.

It likely means the calendar grouping you've selected in the software doesn't match any column in the imported CSV file. Make sure your CSV includes the calendar grouping column you've selected, or remove the grouping from the software settings before importing.

Groupings can be used to apply logic across a range of periods.

In Client > Export activity areas, you can group scheduled slices by a shared calendar value (e.g., Week1, Month2) to merge them into a single export.

When you import a calendar with different period timespans, the software automatically recalculates time usage field values to match the new calendar structure.

You initially use a monthly calendar:

|

Period Name |

Period Start |

Period End |

|---|---|---|

|

January |

1/1/2026 12:00 AM |

2/1/2026 12:00 AM |

|

February |

2/1/2026 12:00 AM |

3/1/2026 12:00 AM |

|

March |

3/1/2026 12:00 AM |

4/1/2026 12:00 AM |

With these time usage field values (refer to Client > Resources tab):

|

Resource |

Field |

January |

February |

March |

|---|---|---|---|---|

|

922-1 |

Availability |

90% |

95% |

90% |

|

Utilisation |

87% |

90% |

84% |

|

|

Efficiency |

92% |

75% |

70% |

|

|

Rate Factor |

100% |

85% |

100% |

You then import a weekly calendar. The software recalculates the field values for each week based on the overlap with the original monthly values.

Based on the new calendar, the software recalculates the availability, utilisation, and efficiency fields for each resource.

Availability is weighted by the duration of each overlapping period.

Utilisation is weighted by (Utilisation × Availability).

Efficiency is weighted by (Utilisation × Availability × Efficiency).

This ensures that the new values accurately reflect the original data, proportionally distributed across the new calendar.

|

Resource |

Field |

W1 |

W2 |

W3 |

W4 |

W5 |

W6 |

W7 |

W8 |

W9 |

W10 |

W11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

922-1 |

Availability |

90% |

90% |

90% |

90% |

93% |

95% |

95% |

95% |

92% |

90% |

90% |

|

Utilisation |

87% |

87% |

87% |

87% |

89% |

90% |

90% |

90% |

87% |

84% |

84% |

|

|

Efficiency |

92% |

92% |

92% |

92% |

82% |

75% |

75% |

75% |

72% |

70% |

70% |

|

|

Rate Factor |

100% |

100% |

100% |

100% |

91% |

85% |

85% |

85% |

94% |

100% |

100% |

Cell colours indicate the origin of each weekly value based on the original monthly calendar: blue cells derive from January, yellow from February, and orange from March. Green cells represent transitional weeks that span two months, with values proportionally averaged between the overlapping periods.

In the Material flow diagram, movements (such as arcs from a stockpile to a crusher) can be assigned quality objectives. These objectives define the desired material specifications—such as grade thresholds or contaminant limits—that must for the material moving over the specified movements.

When generating the Product Optimiser schedule, the software plans and optimises the flow of material from the pit loading points to the final destinations, aiming to meet these quality objectives for each movement. For example:

The movement from a crusher to a final product could require a gold grade between 0.6 and 0.7.

Movements to the final LGSx product might require a minimum gold grade of 0.45.

The optimiser controls material movements to meet these targets as closely as possible.

Traditionally, the Product Optimiser achieves product quality objectives by allocating material to destinations (e.g., crushers or wash plants) and sending any excess to stockpiles. However, at some mine sites this approach isn’t viable.

The Reduce Production to Achieve Blend feature allows the scheduling engine to dynamically adjust the production of mining equipment (e.g., shovels or diggers) across entire periods. This helps meet product quality objectives on movements.

This functionality is useful in operational contexts where:

Stockpiling is limited or unavailable. For example, due to environmental constraints, space limitations, or operational policies that restrict material rehandling.

Short-term scheduling accuracy is critical, such as in shift-based planning, where quality targets must be met within narrow timeframes rather than averaged over weeks or months.

In such cases, the schedule cannot rely on sending excess material to stockpiles to balance quality. Instead, it must control the flow of material at the source by adjusting how much each resource contributes.

To enable this feature, it must be activated at both the site level and for the individual resources involved.

Turn on Reduce Production to Achieve Blend in Site Configuration > General and Calendar Settings.

Enable Variable Dig Rates in Config > Resources.

Once the feature is enabled, the Product Optimiser can dynamically adjust the production rates of constrained resources that contribute to movements with quality objectives. The optimiser controls material flow at sources by modifying how much each resource produces during a scheduling period.

To achieve this, the optimiser inserts delays into a resource’s periodic task list. These delays reduce the total time available for production, effectively lowering the resource’s output for that period. The length of each delay is calculated to help the resource reduce its contribution enough to meet the blend objectives.

While reducing production increases the likelihood of meeting quality targets, it doesn’t guarantee success. If the blend objectives still cannot be met, the schedule may be infeasible. In such cases, the objectives or material flow configuration may need to be adjusted to create a more realistic plan.

Production will never be reduced below the minimum production rate defined for the period (see Minimum production below).

These reductions are reflected in the Gantt chart.

The actual production rate of the resource within a period reflects these dynamic changes.

If a resource is delayed, a task labelled Optimiser Delay is inserted into the resource’s row.

Each resource includes a Minimum Production Rate field (refer to Client > Gantt Chart), defined as a factor between 0 and 1 (e.g., 0.5 means the resource can be slowed to 50% of its maximum rate across the period). This factor can vary by resource and period.

If a resource has:

A base production rate of 1,000 t/h across all periods

A minimum production rate factor of 0.5

The optimiser can reduce its rate to 500 t/h during periods where slowing production helps meet blend targets.

Rehandle groups allow you to model the physical rehandle of material from a stockpile to another location using actual resources like loaders or conveyors. While the Product Optimiser (PO) determines optimal flows based on blending and quality targets, these flows are virtual by default. Rehandle groups bridge this gap by linking physical resources to specific material movements, providing accurate planning and reporting.

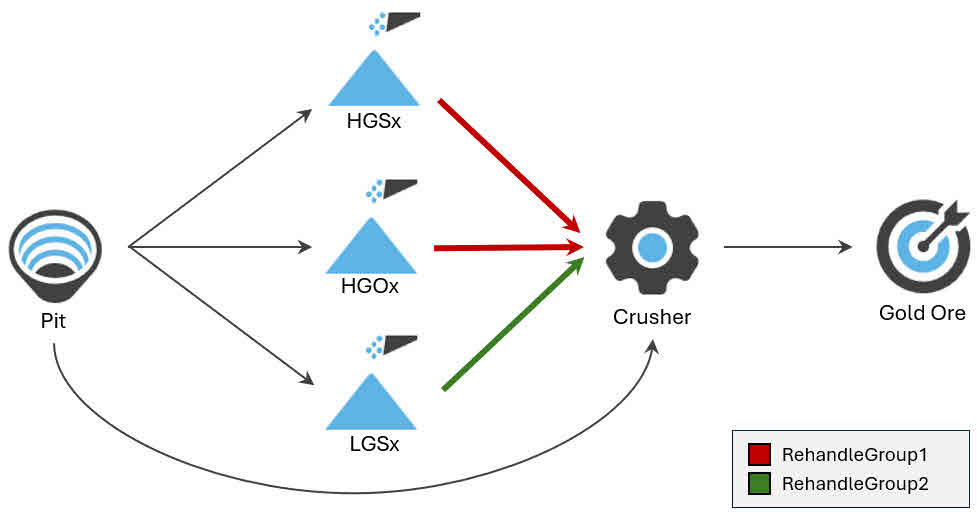

A rehandle group represents a set of material movements (arcs) between a stockpile and another intermediate or a final location (e.g., stockpile → crusher). These groups are defined in the Material flow diagram and are used to associate physical resources with specific rehandling tasks.

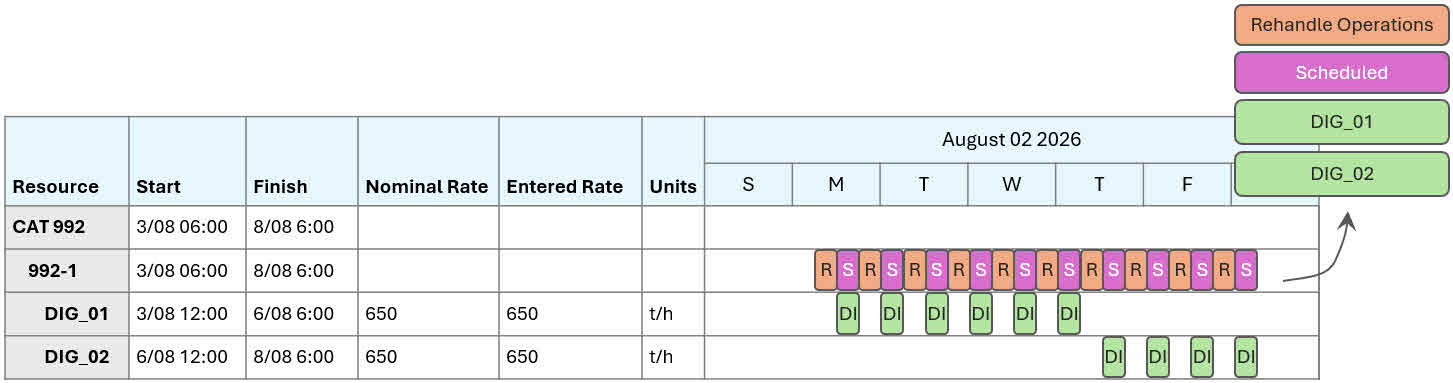

A resource can perform rehandling on a rehandle group’s movements. To set this up, allocate the resource to the Rehandle Operations activity. This activity is system-defined and configured in System Config > Resources.

Each rehandle resource has time usage fields (refer to Client > Resources) that define how much of the resource’s available operating time can be allocated to each rehandle group per period.

A resource’s total allocation across all rehandle groups must be 0% or 100% per period.

The schedule uses these allocations to determine how much material each resource can move per group per period.

Differences in available time (e.g., due to rosters or delays) affect a resource’s total available operating time.

Resources cannot perform in-pit and rehandle group activities in the same period, but they can switch between them across periods.

Each resource’s contribution to a rehandle group is based on:

Its rehandle rate (tonnes/hour)

Its percentage allocation to the group

Its available operating hours (based on shift length, availability, and utilisation)

These values determine how much material the resource can move in a given period.

A site has the following rehandle groups:

|

Group |

Movements |

|---|---|

|

Group1 |

HGSx Stockpile → Crusher HGOx Stockpile → Crusher |

|

Group2 |

LGSX Stockpile → Crusher |

The site has the following resources:

|

Source |

Activities |

Rate (t/h) |

Shift/Period Length |

Total Delays |

Operating Time |

|---|---|---|---|---|---|

|

Resource1 |

Rehandle Operations |

800 t/h |

12 hours |

30 mins |

11.5 hours |

|

Resource2 |

Rehandle Operations |

800 t/h |

12 hours |

30 mins |

11.5 hours |

The resources have the following rehandle allocation percentages (defined in Client > Resources). These allocations are the same across each period.

|

Resource |

Rehandle Group |

% Time |

Max Time |

Max Moved (t) |

|---|---|---|---|---|

|

Resource1 |

Group1 |

60% |

6h 54m |

5,520 |

|

Group2 |

40% |

4h 36m |

3,680 |

|

|

Resource2 |

Group1 |

100% |

11h 30m |

9,200 |

|

Group2 |

0% |

0h 0m |

0 |

For each resource:

The maximum amount of time that can be spent operating on a rehandle group is shown.

This is calculated by getting the % Time percentage of the resource’s available operating time (11.5 hours).

The maximum amount of moved material is also shown.

This is calculated by taking the available operating time and multiplying it by the resource’s hourly production rate.

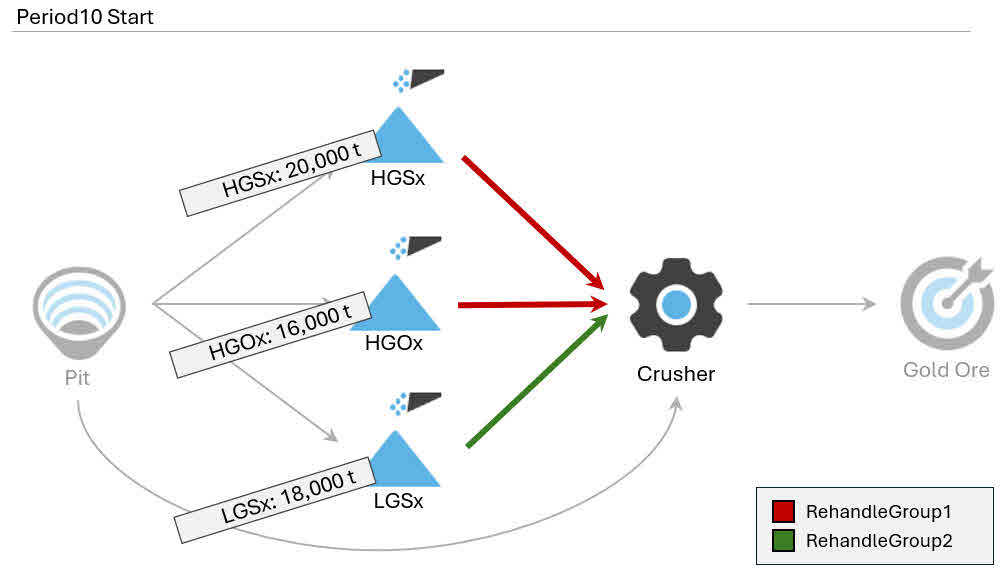

The stockpile inventories at the start of Period 10 are shown below.

|

Stockpile |

Inventory (t) |

Rehandle Group |

|---|---|---|

|

HGSx Stockpile |

20,000 |

Group 1 |

|

HGOx Stockpile |

16,000 |

Group 1 |

|

LGSx Stockpile |

18,000 |

Group 2 |

To allocate resources, the schedule respects the resource limits (refer to Resource allocation per period above) per group:

Group1: Resource1 (5,520 t) + Resource2 (9,200 t) = 14,720 t (max moved per period)

Group2: Resource1 only = 3,680 t (max moved per period)

The Product Optimiser attempts to get only one resource to mine from a given stockpile at a time. Before another resource can mine from a stockpile, the other resource must exhaust its capacity on the stockpile within the period. This isn’t always possible – but it’s the likely allocation scenario.

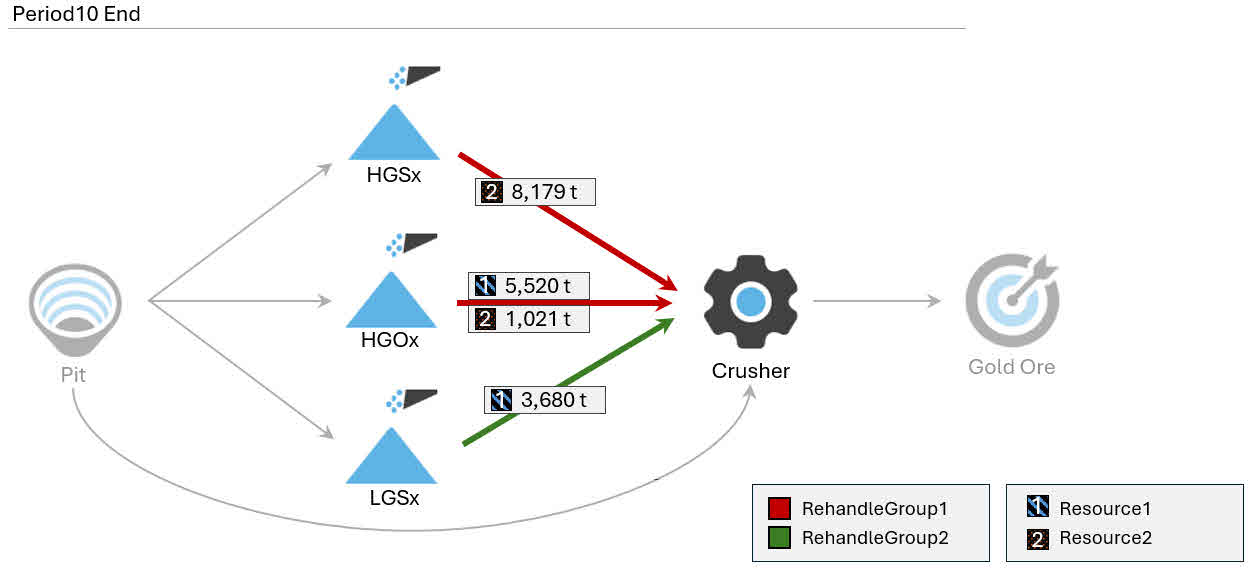

A possible allocation plan for rehandling in Period 10, based on the logic and constraints, is shown below.

Resource2 rehandles all tonnes from Group1’s contribution to HGSx (8,179 t).

Resource2 then rehandles some of Group1’s contribution to HGOx (1,021 t).

The resource’s periodic capacity (800 t/h × 12hrs = 9,600 t capacity) prevents the resource from rehandling more of HGOx.

Resource1 then mines as much as it can from HGOx, following its Group1 contribution (5,520 t)

Resource1 then mines as much as it can from LGSx, following its Group2 contribution (3,680 t).

|

# |

Resource |

Group |

Stockpile |

Tonnes Moved |

Resource capacity |

|---|---|---|---|---|---|

|

1 |

Resource2 |

Group1 |

HGSx |

8,179 |

9200 t |

|

2 |

Resource2 |

Group1 |

HGOx |

1,021 |

|

|

3 |

Resource1 |

Group1 |

HGOx |

5,520 |

9,200 t |

|

4 |

Resource1 |

Group2 |

LGSx |

3,680 |

The list of rehandling tasks performed within this scenario in Period10

|

Stockpile |

Original Inventory |

Tonnes Moved |

New Inventory |

|---|---|---|---|

|

HGSx |

20,000 |

8,179 |

11,821 |

|

HGOx |

16,000 |

6,541 |

9,459 |

|

LGSx |

18,000 |

3,680 |

14,320 |

The stockpile inventories and movements in Period10

The distribution of resources across stockpiles within a group may vary depending on scheduling logic. This example shows one valid allocation that meets all constraints.

The production rate of a rehandle resource is set in System Config > Resources.

Each rehandle group can have an unlimited or limited capacity.

Limited capacity

When enabled, the schedule applies a constraint to each rehandle group that limits how much material can be moved across its movements (arcs) in each period. This limit is calculated based on the combined capabilities of the resources assigned to the group.

For each resource, the system considers:

Its rehandle rate (tonnes per hour)

The percentage of its time allocated to the group

Its available operating hours (based on shift length and time usage fields)

These values are used to calculate how much material each resource can contribute to the group in a given period. The total group capacity is the sum of these contributions. The schedule ensures that the total material moved within the group doesn’t exceed this calculated limit.

Unlimited capacity

No constraints are applied, allowing unrestricted movement across the group’s arcs during scheduling.

If the material moved across the rehandle group exceeds the amount that the resources can handle, the schedule increases the resources’ production rates to accommodate all the material. A schedule warning flags this.

Resources obey roster breaks and exceptions.

Resources try to continue the same task from the end of the previous period into the start of the next to minimise unnecessary movement.

Reclaiming from staged stockpiles respects:

LIFO order (if applicable)

Maximum number of concurrent reclaiming piles

Reclaim swapping penalties (start, middle, end of period)

Rehandle groups don’t enforce:

Staged stockpile filling limits

Instantaneous reclaim rate limits (only total per period)

Arcs can belong to only one rehandle group.

Rehandle groups can only include arcs from stockpiles or staged stockpiles.

Resources can’t be assigned to both in-pit and rehandle activities in the same period.

Rehandle resources are displayed on the Gantt chart (see Gantt Chart) like any other resource. When these resources perform rehandling tasks, a Rehandle Operation bar is shown to indicate the activity. These rehandling delays are non-adjustable directly on the chart.

You can assign in-pit activities to rehandle resources, provided those resources are permitted to perform such tasks.

You can build custom reports (refer to Reporting tab) and Gantt charts (refer to Gantt Reporting tab) to see the full detail of each material movement assigned to a rehandle group, such as the:

Source and destination of each movement

Quantities and qualities of materials

Rehandle group names and associated tasks

Custom Gantt charts can integrate rehandle tasks with other operational schedules, such as in-pit mining, plant maintenance, and train logistics. This unified view helps identify dependencies and optimise coordination across different activities.

For example, a custom Gantt chart could display:

The sequence of rehandle tasks across each period

Locations (e.g., stockpiles) as primary visual elements

Resources such as fixed plant, mobile equipment, and other machinery

Interdependencies between schedules (e.g., how plant maintenance affects train operations, train allocations to specific stockpiles)

Live and dead stockpile locations

For staged stockpiles, the report can display detailed build sequences, including stacking and reclaiming start and finish times. These tasks provide a complete picture of stockpile activity alongside rehandling operations.